- #Cnc usb controller software motor tuning how to

- #Cnc usb controller software motor tuning install

- #Cnc usb controller software motor tuning manual

- #Cnc usb controller software motor tuning code

This is the configuration code for the firmware that you are about to flash to your Sonoff.

There are video tutorials that explain this. Open the ESPHome interface and add a node, fill out the wifi info, device name, etc.

#Cnc usb controller software motor tuning install

Next, you will need to install the ESPHome Home Assistant Add-on from the Add-on Store.(ISO 14443A standart tags) Features: MFRC522 chip based board Operating frequency: 13.56MHz Supply Voltage: 3.3V Current: 13-26mA Read The card reader and the tags communicate using a 13.56MHz electromagnetic field. In this example we will connect an RFID-RC522 module and connect to a Wemos Mini The microcontroller and card reader uses SPI for communication.ESPHome firmware is installed on the ESP8266, allowing automation via Home Assistant. An encoder to track rotations, along with an end stop switch for homing duties. When a stepper motor wasn't able to lift the heavy blinds, a 40 RPM geared DC motor was instead implemented to accomplish the task in around 20-30 seconds.The content :) Initial concept I've had a simple eWeLink relay in the gate box for a while now, which can help me open and close it remotely. I have a Centurion gate motor they are a popular gate motor supplier in South Africa and they also have their own lineup of home automation products.A few months later, the company would formally announce development of the huge New Glenn rocket.

#Cnc usb controller software motor tuning how to

#Cnc usb controller software motor tuning manual

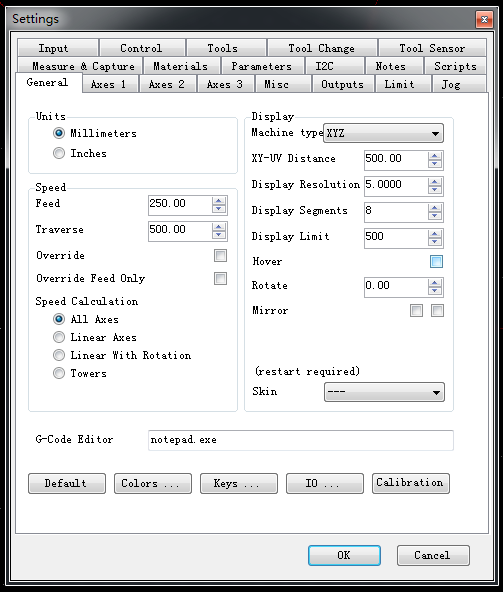

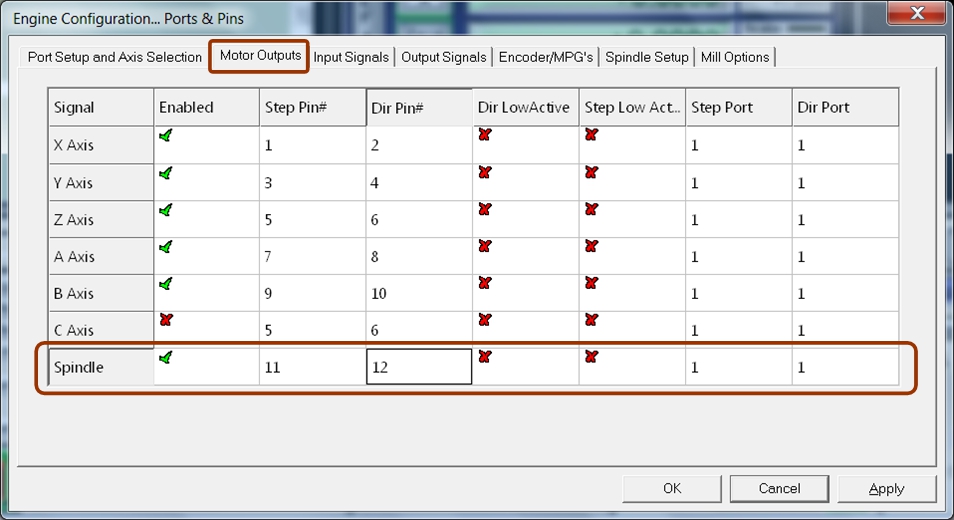

Kind note: if you bought the mini CNC machine or any hobby CNC router from ChinaCNCzone, you can download the relatated manual from our download center as below link. Backlash Can be set for each axis hysteresis Stops Set PACK1, PACK2 information. Be careful to set these parameters, serious adjustment. Maximum Speed Please set up the machine movement is not lost step value. Acceleration value is smaller, the maximum speed from the initial speed to the longer time-consuming, the more stable the motor. Acceleration Movement started from the initial velocity (units / min) and speed (units / second squared) to the maximum speed. Ball screw pitch is generally 5MM, axes should be set to 320 the number of steps Reverse Set against the direction of movement Level inverter Some motor drives with a total of yin yang connection of different correlation. Trapezoidal screw pitch is generally 4MM, axis number of steps to be set to 400. Pulses / step Set the number of pulses per unit, this value is very important, please use the basic settings after setting the calibration function tests. Second, X,Y,Z,A axis parameters setting as below picture, please kindly specially notice the A axis parameters(the 4th axis setting) How to set X,Y, Z, A axis of CNC 6040 and CNC 6090 in USB CNC Controller Software? Mini CNC router made by ChinaCNCzone such as CNC 3040, CNC 6040 and CNC 6090 series have USB CNC controller version for selection.

0 kommentar(er)

0 kommentar(er)